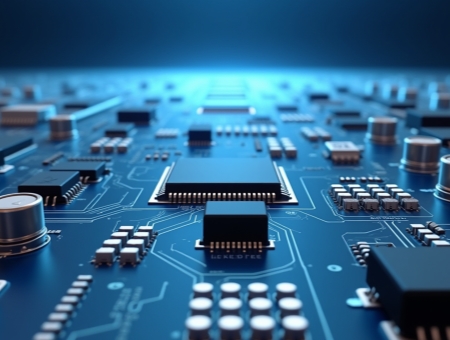

Glass&LED substrates

As an additive,α Alumina Powder enhances the hardness,impact resistance and wear resistance of glass, making it suitable for specialty glass, bulletproof glass, and high temperature resistant glass application.

LED substrates fabricated from α Alumina powder exhibit exceptional thermal conductivity ,high mechanical strength,superior flatness,effective heat dissipation ,and excellent chemical stability,thereby significantly improving LED reliability.